For aircraft interior components and machine parts

Anodic oxide coating (ALUMITE processing) for aluminum molds, plates, panels, construction materials, etc.

Sulfuric acid ALUMITE processing: large 10-meter-long line (effective size: 350 × 1,500 × 9,000)

For aerospace and defense equipment and other precision machinery

Title: Launch of H-IIA F11 from PST

Photo courtesy of: Japan Aerospace Exploration Agency (JAXA)

Surface treatment of aluminum and its alloys for precision parts, housings, and other precision machinery

Acquired JIS Q 9001:2015/ISO 9001:2015 quality management system certification

Registration number: JMAQA-258

For surface treatment of aluminum and aluminum alloys, we have obtained process approval from MHI, KHI, FHI, IHI, and

others.

For certification status, we publish the list of special process and management status twice a year.

If you would like a copy of the list sent to you, please contact our Sales Section or Quality Assurance Technical Section.

- Sulfuric acid method anodizing processing (sulfuric acid ALUMITE, white ALUMITE, color ALUMITE)

- * Conforms to MIL-PRF-8625F (MIL-A-8625) Type II and various other standards

- Hard anodized processing (hard ALUMITE/hard anodization)

- * Conforms to various standards, such as MIL-PRF-8625F (MIL-A-8625) Type III

- Oxalic acid anodized processing (oxalic acid ALUMITE)

- Please contact our sales department for available sizes and other information.

- Chrome acid anodized processing (chrome acid anodization)

- * Conforms to various standards, such as MIL-PRF-8625F (MIL-A-8625) Type I and IB.

◎Seal processing such as nickel acetate seal, dichromate seal, steam seal, hot water (deionized water) seal, etc. can be selected according to the purpose of use.

- Chemical coating treatment (chemical conversion coating treatment, ALODINE processing)

-

IRIDITE 14-2, ALODINE 1200/1000

*MIL-DTL-5541F TypeI Class1A/Class3

Conforms to MIL-C-5541E Class1A/Class3 and various other aerospace standards

IRIDITE14-2 is registered for QPL-81706 certification.

(Pretreatment for bonding)

Acid etching (dichromate - sulfuric acid solution)

Automobile engine valves

Hard chrome plating for industrial use

We specialize in the mass production of parts with diameters of 6 to 12 mm.

Single-layer plating with plating thicknesses of 5 µm, 10 µm, 15 µm, 20 µm, 40 µm, etc. on steel, heat-resistant steel, corrosion-resistant steel, etc. greatly improves the durability of products.

Surface treatment of aluminum

Launch of H-IIA F11 from the second camera room

“Photo courtesy of: Japan Aerospace Exploration Agency (JAXA)”

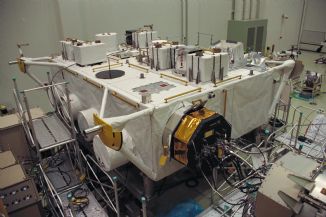

JEM system engineering model (EM)

Photo courtesy of: Japan Aerospace Exploration Agency (JAXA)

Aluminum is light, highly conductive, and has a beautiful silvery white color, but it is soft, easily corroded, has poor

coating adhesion and durability, scratches easily, and is prone to surface aging such as white rust and discoloration,

which limits its use as a metal material.

Anodic oxide coatings (ALUMITE) prevent scratches and wear by hardening the surface and increase corrosion resistance,

making aluminum suitable for a wide range of applications.

Conversion coatings (chromate) increase the corrosion protection of aluminum and also greatly improve the adhesion and

durability of the coating.

* If you have any issues with aluminum surface treatment, please do not hesitate to contact us. We will be happy to help you.

Our surface treatment methods allow aluminum to be used in a wide range of industries.

In addition to continuing to refine the technology and quality that we have developed in the aerospace industry, providing technology and reliable quality for a wide range of industries and developing technology to meet new needs.

Riken Alumite Industry has been certified by various aerospace manufacturers, such as Mitsubishi Heavy Industries Ltd.,

Kawasaki Heavy Industries, IHI Corporation, and IHI AEROSPACE Co., Ltd.

For certification status, we publish a "List of Special Process and Management Status" twice a year. If you would like a copy of the list sent to you, please contact our Sales Section.

We are also willing to handle oversized products, surface treatment for which it is difficult to find a suitable processor, seal treatment not listed in catalogs, etc.

If you have any issues with aluminum surface treatment, please do not hesitate to contact us.

Our anodized processing provides you with peace of mind.

If you want a perfect seal, we can provide you with a pressurized steam seal (available dimensions: 700 × 600 × 5,000 mm).

◆Acquired ISO 9001 Quality Management System Certification

ISO 9001:2015/JIS Q9001:2015

Registration number: JMAQA-258

Audit scope:

Surface treatment of aluminum and aluminum alloys applied to the surface treatment of metal products commissioned by customers at the head office plant, covering all departments of the head office plant.

(The main surface treatments are anodized processing and chemical conversion coating)

◆Large-scale ALUMITE processing equipment for 8th generation LCD manufacturing facilities

Large plates sized 3,250 × 3,250 × 200 mm

(Maximum weight of 0.8 tons) is supported

Low reflectivity black ALUMITE (visible light to near-UV light range)

Black staining is also available for ceramic composite aluminum alloys

Deionized water is used for rinse water. This makes our plant a product- and environment-friendly clean facility.

* The supported dimensions shown are the effective dimensions of the treated layer. Larger sizes than shown may also be available. Please contact our Sales Section for more information.